Any seal. Any time. Anywhere.

Materials

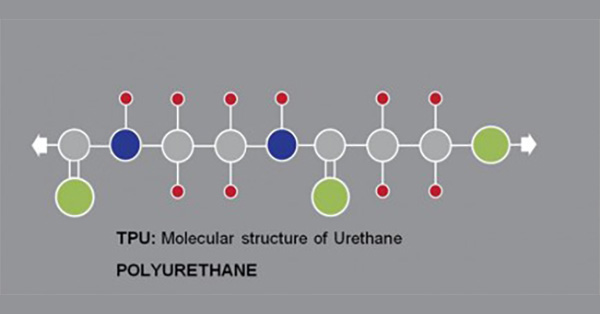

PU – Polyurethane

The diisocyanate type is also crucial. The most commonly used types are MDI, PPDI and TODI. The combination between polyol and diisocyanate typology results in very different products, whose physical and mechanical features – and resulting applications – vary significantly.

The thermoplastic polyurethanes (TPUs) currently on the market are elastomers with high performing mechanical characteristics, featuring excellent tensile strength, as well as very good tearing, abrasion and cutting resistance. They are usually compatible with mineral oils, greases, hydrocarbons and petroleum derivatives.

Standard TPUs normally have poor compatibility with hot water, acids, alkaline solutions and steam. For such applications, specific TPUs have been developed.

Prefix Code:- P9

Hardness:- 95 duro shore A

Colour:- Cream/Clear

Temperature Range:- -40ºC to +195ºC

Prefix Code:- PU95

Hardness:- 95 duro shore A

Colour:- Red

Temperature Range:- -40ºC to +195ºC

Prefix Code:- PU72

Hardness:- 72 duro shore D

Colour:- Blue

Temperature Range:- -30ºC to +125ºC

Prefix Code:- PU58

Hardness:- 58 ± 3 duro shore D

Colour:- Black

Temperature Range:- -25ºC to +110ºC